Performance Composites

Our Anhydride Epoxy hardeners, and fibre fillers are in the latest composite technologies…

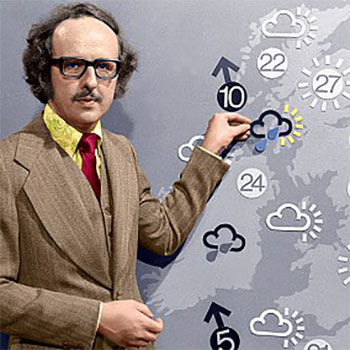

Materials across the globe

Be it small quantities of high value additives, or bulk commodities, our logistic department customises delivery to our business partners` needs.

Paper Polymer Innovation

The evolution of paper technology has introduced the synthetic wood pulps into daily household applications.

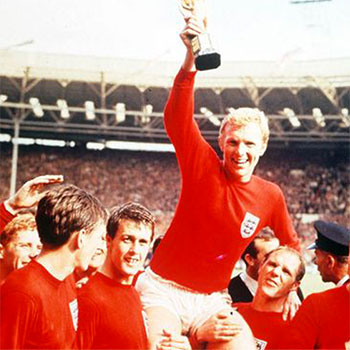

2016 The Golden Year – 50 Years of Sparkford

We’ve come a long way